Digital transformation, smarter manufacturing: Expert interview series, Bernd Raithel, Siemens

Just starting or stalled with digital transformation and smart manufacturing? Gain inspiration and hear advice from Bernd Raithel, director of product marketing and deployment of new technologies at Siemens Factory Automation in the U.S., based on experiences at Siemens manufacturing plants. See video.

Learning Objectives

- Learn what is involved in smart manufacturing and how digital transformation can help.

- See how to identify and prioritize smart manufacturing projects.

- Review smart manufacturing video interview topics with Bernd Raithel, Siemens Factory Automation.

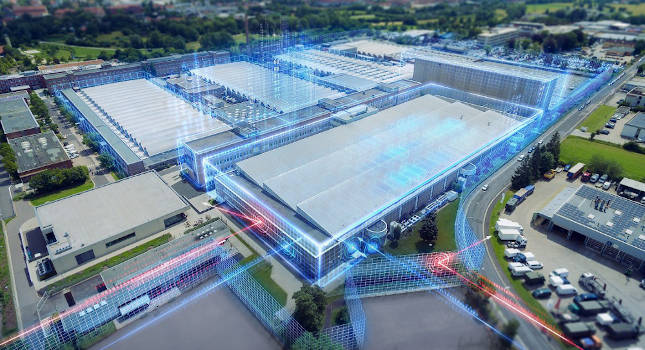

Smart manufacturing can use artificial intelligence (AI), industrial edge computing and cloud computing to enable highly efficient production, such as at the Siemens Electronics Works Amberg (EWA) plant in Germany, and at other Siemens’ manufacturing sites globally.

Bernd Raithel, director of product marketing and deployment of new technologies at Siemens Factory Automation in the U.S. In the video, Raithel talked about trends, challenges, metrics and advice for digital transformation, the journey toward smart manufacturing. Learn from an automation manufacturer, how manufacturing can be more efficient, flexible and productive.

Bernd Raithel, director of product marketing and deployment of new technologies at Siemens Factory Automation in the U.S., discussed smart manufacturing and digital transformation in a Zoom interview with Control Engineering’s Mark T. Hoske, content manager, in September 2021. Courtesy: CFE Media and Technology

What is smart manufacturing and how does digital transformation help?

Smart manufacturing, a very broad term, includes many elements, Raithel said. Smart manufacturing starts with use of computers besides the control system to implement artificial intelligence algorithms, autonomous systems and derive decisions from data received, along with adaptability and flexibility, reacting quickly to design changes, new products and new product variations, helped by development, use and update of digital twins and information from the Industrial Internet of Things (IIoT). Smart manufacturing and Industry 4.0 are quite similar terms and advice for one can be applied to the other. IIoT helps derive data so people can make decisions from it. Digital transformation really describes the journey going from today’s factories to achieving highly automated, smarter factories in the future, he explained.

The highly automated Siemens Electronics Works Amberg plant, built in 1990, retains about the same footprint and same level of employment now with 13 times greater efficiency, to get more products out of the factory, explained Bernd Raithel, director of product marketing and deployment of new technologies at Siemens Factory Automation in the U.S. Courtesy: Siemens Factory Automation

Identifying and prioritizing smart manufacturing projects

The Siemens Electronics Works Amberg plant, built in 1990, retains about the same footprint and same level of employment now with 13 times greater efficiency, to get more products out of the factory. It’s highly automated, with a lot of control systems, supervisory control and data acquisition (SCADA) systems, manufacturing execution systems (MES) to optimize operations, workflow throughput and flexibility in the best possible way with very high quality.

Virtual commissioning is used to validate and test a production line before it is built to show points of constriction and optimize up front. Predictive maintenance in machines reduces downtime and increase throughput. A simulation of the whole factory helps with product changeovers to get the most output. About 1,200 automation products are made in the plant, with total output of 17 million products per year.

Among topics discussed is how people can identify and prioritize digital transformation projects for smart manufacturing. Raithel explained that those involved in digital transformation should look at the pain points. What is holding back productivity, efficiency and flexibility? We make a list of areas to improve and then look at the technologies available to help solve which problems, looking at the best return on investment.

Siemens Electronics Works Amberg plant includes control systems, supervisory control and data acquisition (SCADA) systems, manufacturing execution systems (MES) to optimize operations, workflow throughput and flexibility in the best possible way with very high quality, explained Bernd Raithel, director of product marketing and deployment of new technologies at Siemens Factory Automation in the U.S. Courtesy: Siemens Factory Automation

Smart manufacturing video interview topics

The smart manufacturing video interview includes the following topics.

- Introduction to Bernd Raithel, director of product marketing and deployment of new technologies at Siemens Factory Automation in the U.S.

- Smart manufacturing defined, other optimization terms

- Before and after digital transformation at Siemens Electronic Works Amberg

- Smart manufacturing and digital transformation projects and return on investment

- Challenges of smart manufacturing and ways to overcome them

- Smart manufacturing benefits, project selection, continuous improvements

- How to learn more (see also links provided).

Bernd Raithel is director of product marketing and deployment of new technologies at Siemens Factory Automation in the U.S. Edited by Mark T. Hoske, content manager, Control Engineering, CFE Media, mhoske@cfemedia.com.

KEYWORDS: Smart manufacturing, digital transformation

CONSIDER THIS

Is your digital transformation toward smarter, more resilient manufacturing accelerating?

Manufacturers Alliance Foundation provides more smart manufacturing information at the Oct. 19-21 virtual Manufactured Summit “Fast Track the Future: Strategies for Manufacturing’s Next Era.”

Bernd Raithel at Siemens Factory Automation invited LinkedIn contact.

Related Control Engineering smart manufacturing articles include:

https://www.controleng.com/articles/digitalization-automation-advice-benefits/

https://www.controleng.com/articles/are-we-far-from-digital-factories/

Do you have experience and expertise with the topics mentioned in this content? You should consider contributing to our CFE Media editorial team and getting the recognition you and your company deserve. Click here to start this process.